Infrastructure

CD 102 Heidelberg Offset Machine

This machine is used for label printing and many other printing needs. It is a collection of machines rather than a single press and has a very quick turnaround time for printing jobs. Moreover, we use it for its robust construction that provides the perfect print quality.

- Reduces waste generation

- Uses energy-efficient technology

- Includes an intelligent automation system

- Maximises press uptime

Automatic Die Cutting & Creasing Machine

This machine cuts and shapes materials into precise patterns and designs. It is high-speed and can be fed accurately via a specially designed feeder. Its automation system helps with easier diagnosis and troubleshooting of issues, ensures quick execution and minimum downtime, and supports a quick changeover operation.

- Provides continuous production

- Adjustable feeder timing

- Perfect positioning system

- Computerised control

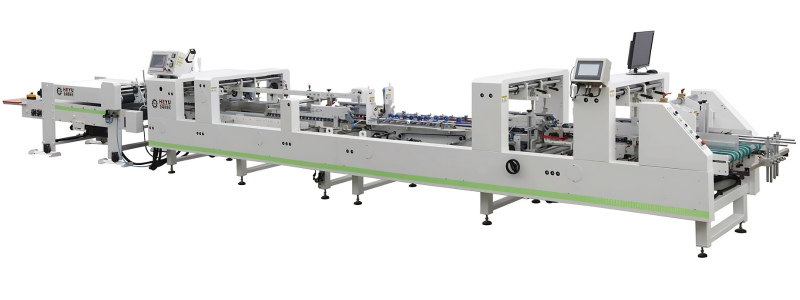

Automatic Folder Gluing Machine

This machine has a heavy-duty construction and a motorised carrier movement which helps reduce labour and provides personalised packaging. That’s why it can handle heavy corrugated boxes for various industries. It is used as a box folding gluer, has a modular design and includes automation.

- Supports high-speed folding and gluing

- Rotatory hooks ensure correct folding

- Includes Human Machine Interface (HMI)

- Supports continuous usage

Rotogravure Printing Machine

This machine is controlled by an advanced drive system and supports automatic cutting and splicing. Its tension gets adjusted via a floating roller. It has a high printing accuracy, even at a faster speed, supports video inspection and has a servo motor controlling system.

- Ensures lower wastage

- Includes higher precision

- Contains a heavy-duty doctor blade

- Uses heat pump heating device

Solventless Lamination Machine

It is a lightweight laminating and coating machine and avoids solvent migration, which means the solvent from one material does not mix into another. Its job memory supports repeated tasks, while its auto machine pre-setting ensures it stops or starts working at a specific time.

- Online diagnostic system

- Touch screen interface

- User-friendly layout

- PLC-controlled machine functions

Horizontal Slitting Machine

This machine is used for heavy-duty horizontal cutting. It can cut single layers of PET, PVC, papers, multilayer films and other materials. It has a programmable control system and requires simple input parameters such as the speed, diameter and thickness of the raw material.

- Stability at high speed

- Supports frequency adjustment

- Convenient unloading

- PLC (Programmable Control System)

3 Side Seal Zipper Pouching Machine

It is a high-speed sealing bag-making machine. It saves effort and time as it can work on hundreds of bags in a minute and is mostly used for industrial purposes. It has a PLC control and uses a 3-side sealing method and can be used for various industries such as FMCG, cosmetics, etc.

- Moisture resistance

- Ideal for 3-sided sealed bag products

- Low heat sealing

- Supports automation